Control of hazardous chemicals

Product Compliance, Audits and Certifications: E.Miroglio overcomes challenges in textiles with SDS FullService

E.Miroglio

The fashion industry has been in the crosshairs for years because of its manufacturing impact on human health, the environment and the difficulties associated with the disposal, reuse and recycling of huge quantities of products containing toxic substances.

It is no coincidence that we are increasingly hearing about green fashion, a trend fueled by growing market and consumer interest in sustainability. This movement, along with compliance with numerous current regulations, is driving companies in the industry to be extremely careful about hazardous chemicals in materials and manufacturing processes, with the goal of reducing their use or replacing them with alternatives that are less harmful to health and the environment.

"Our commitment to removing harmful substances from production has allowed us to be certified as a supplier of companies that meet Greenpeace's highest Detox standards."

Stefano Gusi

Plant Manager

In this context, companies like Edoardo Miroglio stand out for adopting innovative solutions to control and manage hazardous chemicals, demonstrating that fashion and chemistry can work together to create a more sustainable world.

By partnering with Every Software Solutions, E.Miroglio has simplified and automated chemical control processes in compliance with public, industry and private MRSLs (Manufacturing Restricted Substances Lists) and major Textile Certifications, while also achieving tangible benefits in inspection visits, audits and certifications.

"We are fully satisfied with the monitoring process achieved and the 'appreciation' shown by our clients for the data we are able to produce in audits."

Christian Cecchelero

Quality Control Manager

Edoardo Miroglio: specialization, creativity and passion

Edoardo Miroglio is a major European textile company, with seven production and administrative units distributed between Italy and Bulgaria.

It is a steadily growing company and has positioned itself in just a few years among the world leaders in the production and sale of yarns, shuttle fabrics and knitted fabrics.

It is undoubtedly among the first companies in the industry to have guided its production with a conscious and responsible vision, paying special attention to the selection of raw materials and suppliers.

"Our focus begins at the raw materials research stage, where we look for the best possible materials. Our goal is not only to source ethical materials, but also to take into consideration the possibilities of recycling and reuse, in order not to further pollute the environment."

Stefano Gusi

Plant Manager

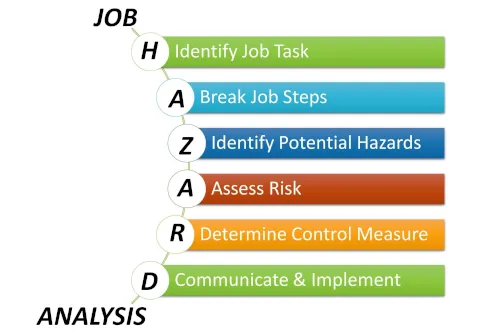

The needs and most critical factors in chemical control

Let's examine the factors and critical issues that led E.Miroglio to search for a solution that can digitalize and automate Safety Data Sheets (SDS) and chemical management processes.

1. Compliance with regulatory and industry lists (public lists).

The company, like all domestic manufacturing companies, is obliged to operate in compliance with the REACH Reg. (European Chemical Regulation), Legislative Decree 81/2008 (National Unified Workplace Health and Safety Standards) and Legislative Decree 152/2006 (National Unified Environmental Regulations Framework) and is therefore subject to the restrictions on the use of chemicals on the Lists issued by ECHA (European Chemical Agency).

Its membership in the fashion supply chain also sees it committed to compliance with industry lists (ZDHC MRSL) and regulations issued by exporting countries(California Proposition 65).

2. Conformity to Fashion Brands.

Over the past few years, many fashion brands are recognizing the importance of controlling hazardous chemicals as an integral part of their marketing strategy. To this end, they have developed additional lists of banned substances and customized protocols that suppliers, such as E.Miroglio, must follow, including strict requirements and regular inspection visits to production facilities.

3. Compliance with textile certifications

The path of sustainability undertaken by E.Miroglio has led to the acquisition of various certifications (ECOLABEL, OEKO-TEX, GRS, etc.) that are awarded to companies that comply with strict environmental rules and impose stringent controls on the use of chemicals.

4. High turnover rate of the Safety Data Sheets

In a dynamic and innovative business such as E.Miroglio, which launches two new collections annually, monitoring processes must be rapid and continuous. The frequent introduction of new colors and eco-friendly chemicals generates a high SDS turnover rate.

5. Constant updating of public lists

Increased awareness of the impact of chemistry on the environment and society is leading to continued adjustment and increase in regulatory and industry MRSLs (ECHA Lists, California Proposition 65, and ZDHC).

All these factors contributed to a significant increase in work in monitoring processes: the company could no longer limit itself to manual management of SDSs and hazardous substance lists.

"Manual handling of these activities required an unsustainable effort, a great expenditure of time and resources, and involved potential risks."

Christian Cecchelero

Quality Control Manager

Solution identified: SDS FullService

After careful evaluations, E.Miroglio chose SDS FullService from Every Software Solutions, which offers innovative digital services and solutions that can:

Transform SDSs into a structured database of chemical product information

Centralize the storage and management of SDSs

Enable immediate and effective searches

simplify compliance audits

generate reliable reporting

Integrate and maintain up-to-date public MRSLs

Integrate private lists of company interest

Underlying the SDS FullService offering is Share-SDS, a cloud-delivered solution guaranteeing scalability, security and rapid project implementation, which includes:

-

- Share-SDS Drive: organized management of SDSs received from suppliers and digital archive of hazard data for substances and mixtures

- Watchlist Monitor: management for monitoring hazardous substances in the company with continuous comparison with MRSL substance lists

Crucial in the selection and "flagship" of the software solution were SDS Full Service's distinctive services, which include:

-

- The automatic SDS content extraction and indexing service, which is integrated into Share-SDS Drive and is a prerequisite for a structured and reliable database

- The integration and continuous updating of public, industry and private lists in Watchlist Monitor

"Through the process of digitalization of SDSs and automatic integration of ECHA, California Proposition 65, ZDHC and private lists, I easily have all hazardous chemicals that are banned or restricted for use under control."

Christian Cecchelero

Quality Control Manager

The phases and timing of the Project

The SDS FullService adoption project, which began in 2022, involved four departments at the Italian plants in Valli del Pasubio, Vicenza: Dyeing, Technical Plants, Maintenance and Sample Cloth Treatments.

In order to create the initial archive of SDSs in Share-SDS, the SDSs already present in the plants were collected and verified, the digitalization, the census and subsequent cleaning of duplicate or obsolete SDSs as well as the search for new versions from suppliers.

This phase, which lasted about 1 month, started with the assessment of the collected documents, which were then consolidated into the creation of an archive consisting of about 300 SDSs, corresponding to about 1,000 substances and mixtures to be managed.

At the same time, key steps for automating recurring activities of the SDS management process were analyzed and organized.

1. Organization of the Entrance of SDSs.

A structured system has been established to receive and record SDSs in an organized manner that channels the documents into Share-SDS Drive. The system sends notifications for the entry of new SDSs or Revisions to users responsible for verifying incoming SDSs from suppliers.

2. Extraction and indexing of SDS contents.

Incoming SDSs in Share-SDS Drive are immediately initiated to the automatic data extraction and indexing process.

3. Workflow-managed validation, approval, and deployment

An automated workflow has been established for validation and approval of SDSs, which, at each key step, sends email notifications to the offices involved for their relevant activities:

- Quality Control Office

- H&S

- Plant Manager

At the end of the workflow, SDSs are organized by distinguishing in-use products from discontinued, rejected, or exhausted products.

4. Monitoring of MRSLs

All indexed SDSs flow into Watchlist Monitor, which cross-checks the substances in the SDSs against the following integrated MRSLs:

-

public lists

- ECHA (Candidate, Authorization, Restriction, Registered Substances, Harmonized)

- California Proposition 65

-

industry lists

- ZDHC MRSL

- private lists/customer specifications: Company Black Lists and customer specifications, as well as any substance lists that the Company wishes to monitor for future replacements.

5. Checking Compliance with Certifications

At the request of the Company, appropriate indicators of non-compliance against the Certifications in force have been configured.

A system of indicators promptly flags the presence of SDSs and related non-compliant substances against the Managed Lists or Certifications.

6. MRSL monitoring reports.

In addition to the indicators, a report is generated periodically of changes that have occurred due to the inclusion of new substances on the lists or the entry of new SDSs. An automatic notification system sends the report to the relevant functions for appropriate evaluation and action.

The service of updating public and industry lists is carried out on an ongoing basis directly by Every SWS, while private lists are managed directly by E.Miroglio.

After only a few weeks from the start of the project, E.Miroglio was already able to make full use of the Share-SDS Drive features and the Watchlist Monitor of the Hazardous Chemical Lists: for all SDSs used by the factories automated checking and comparison with more than 6,000 substances on the lists of its interest. It also had direct links to the documentation made available by ECHA (Infocards, Dossiers, Annexes, etc.) for consultations and in-depth analysis of more than 30,000 substances from the Registered Substances List and the Harmonized Substances List, which are also integrated with Share-SDS Drive.

Objectives achieved

In fact, digitalize and automating the chemical management and control process with a specialized and well-established solution such as SDS FullService resulted in the achievement of the goals set by the company without any particular difficulties and in a very short time.

In a nutshell, the project enabled the company to achieve:

Decisions based on reliable and up-to-date data

Immediate searches and consultations on data and documents

Full control of all chemicals in use

ease of data extraction for reporting and internal/external audits

Concrete support for compliance with industry and customer standards and requirements

information, alerts, and automatic notifications about the presence of hazardous, banned, or restricted substances over the entire cycle of use, then:

At the sampling stage by R&D; at the design stage of a product; at the purchasing stage

When being used in production, ensuring occupational health and safety

Being recycled or disposed of in the environment

Digital innovation to support sustainability in the fashion industry

The adoption of SDS FullService has transformed chemical management from a complex challenge to an efficient and reliable process, supporting E.Miroglio in meeting increasingly stringent regulations and adhering to the high standards required by customers.

Ultimately, the story of E.Miroglio is a powerful testimony to the role of technology and innovation in overcoming today's environmental challenges.

"Thanks to SDS FullService, we now quickly and accurately manage the presence of hazardous chemicals. This not only improves the safety and sustainability of our production, but also strengthens our overall commitment to environmental and social responsibility."

Stefano Gusi

Plant Manager

"We achieved excellent results in an extraordinarily short period of time partly because we found in Every SWS a supplier capable of accompanying us with great professionalism and cutting-edge technology. The flexibility and scalability of their solutions allow constant adaptation of the system to our needs."

Christian Cecchelero

Quality Control Manager