Optimize your SDS Archive

The Start up process

Organize your SDS archive with our startup process. From collection to digitalization, we take care of everything to ensure an efficient and up-to-date archive.

An archive of SDSs organized

The first step to proper management of Safety Data Sheets

For the creation of the initial archive of SDSs in SDS-FullService, we proceed with the collection and verification of the SDSs already present in the establishments, the digitalization, the census and the subsequent cleaning of duplicate or obsolete SDSs, as well as the search for new versions from suppliers.

Start up

1 →

Census and Initial Loading of SDSs.

Basic indexing

2 →

SDS Assessment

Cataloging & Assessment

3 →

Cleaning duplicate or obsolete SDSs

Cleaning

4 →

Searching for missing SDSs and new versions

Searching & Loading

5

digitalization completion and archiving of SDSs

Indexing

How to reorganize and put your SDS archive in order?

Archive Safety Data Sheets (SDS) in folders and organizing them via Excel files is a method that is often used, but which has limitations in the reliability of the information, as well as being a manual and very time-consuming activity.

The management of SDSs and related chemical data is a corporate information asset that cannot be managed through folders and files that are difficult to synchronize, update and search.

The SDS-FullService start-up process allows you to quickly centralize all your essential documents and data to allow you a comprehensive view of your SDS portfolio and to choose and execute the appropriate actions.

Do you have your own archive with SDS data that you want to retrieve? SDS-FullService, in its start-up phase, provides specific functionality for importing data already in corporate spreadsheets.

SDS-FullService's Start-up Processes.

Thanks to SDS-FullService solutions and a time-tested methodology, we are able, in a matter of days, to survey and catalog all the Safety Data Sheets in the company.

Census and Initial Loading of SDSs.

After SDSs are collected, they are conveyed to the process of digitalization automatic, which can automatically index the data contained in the SDS PDFs and load them into a centralized enterprise database from which the Cataloging and Assessment service can proceed.

SDS Cataloging & Assessment

Downstream of the initial census and loading of SDSs, with the Cataloging and Assessment process will be possible:

Highlight duplicate Safety Data Sheets

Recognize obsolete SDSs (those with an issue/revision date prior to the most recent)

Identify SDSs related to products no longer in use

Assess the status of updating SDSs for each production site and for each supplier/manufacturer

Schedule (if necessary) update activities for Safety Data Sheets, i.e., requests to be made to suppliers/manufacturers to receive any updates

SDS Cleaning and Research

Once all SDSs have been surveyed and reordered, the cleaning of duplicate or unnecessary SDSs and the shelving of obsolete or discontinued SDSs can be done.

It is also possible to obtain the most up-to-date versions of SDSs for chemicals used by relying on the Search and Upload of SDS-FullService, which independently proceeds to find the Safety Data Sheets you need by contacting the supplier/manufacturer directly.

Obtaining the Centralized TUE Database Safety Data Sheets

(You must accept "Experience" cookies to view the video properly)

At the end of the start-up process the company finally has an organized and clean SDS archive, it is then possible to continue with the digitalization automatic of all the information needed for the management of substances and mixtures.

The creation of the initial SDS repository is the first step needed to address the digital transformation of the SDS Management process. (You can learn more about how to approach digitalization of the SDS Management process by reading our article).

Find out how to order your SDS archive!

A path to learning through concrete examples and cases

Download the White Paper of the SDS Cataloging & Assessment Service for more information, insights, and practical examples!

(Available only in Italian)

Other documents of interest:

Read our article SDS archive management: digitalize, rearranging and optimizing the circulation of documents in the company

Article published in the journal Cosmetic Technology (November - December 2019)

Results of a SDS Cataloging & Assessment Analysis.

An analysis of document material (SDS) was conducted in a company with three production sites, with SDS stored in three network folders containing 713 documents.

This company is considered to be representative of the average companies in the Italian market.

Only a few results related to the documentary analysis that was conducted are presented below.

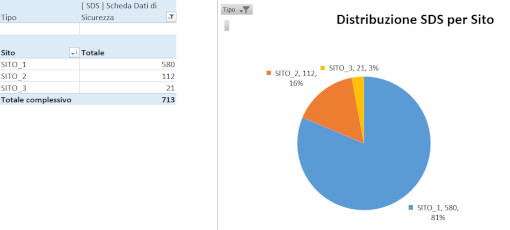

Distribution of SDSs by production site

This is the representation of the distribution of SDS for each production site of a company. The Safety Data Sheets They come from three network folders containing 713 documents.

A total of 713 SDSs were examined and the distribution in the 3 sites related to the same company was ascertained.

- site 1 has the majority of SDSs (> 80%)

- il sito 2 dispone di un centinaio di SDS (<20%)

- il sito 3 solo poche decine (<5%).

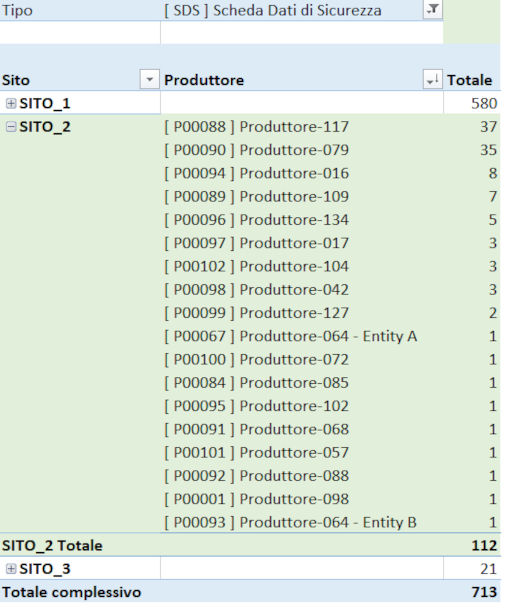

Distribution of each supplier

From the analysis, it is possible to show the distribution of suppliers at the various Sites.

In this example, we see the detail of the manufacturers with the SDS number of Site 2.

Breakdown of SDSs by supplier

The distribution on the A-B-C list of SDSs by document provider is represented in this figure; it has 133 names: the top 27 (20 percent) are providers of as many as 75 percent of the SDSs.

Distribution of SDSs by year and manufacturer

An analysis was also carried out which made it possible to break down the documents by supplier, for the year to which the Safety Data Sheets and vice versa.

The analysis of the review of the various SDSs held allows for the calculation, at the total level and by Site, of the distribution over time with respect to their issuance, as well as a year-by-year scan.

Age index of Safety Data Sheets

It is also possible to calculate the SDS age index, which is the average number of years/months elapsed between the revision date (shown on the document) and the current date.

This data can be obtained at the general level, by Site and by SDS provider. With this index you can quickly understand the average update status of your SDS portfolio.

A good age index is about 2, which means that, on average, the SDSs you have were updated in the current or previous year.

In this case it is noted that it is almost 4 1/2 years old.

Duplication of SDSs

Another significant result is to highlight duplication of owned SDSs, i.e., the situation where there are multiple documents related to the same product, from the same supplier and written in the same language, whether they have the same revision date or different revision dates.

A specific report indicates all such cases and allows the specific situations to be analyzed.

In the first case, as many as 7 SDSs are noted in the SITE_1 folder, with 5 different revision dates.

In the second case, it is noted that SITE_1 has 2 SDSs, with different revision dates, but it is also determined that SITE_3 has only the "old" version of the SDS, which would lead to the conclusion that the document update was not made available at this site.

Once identified, duplicate SDSs are removed and only one document is retained, the one with the most recent revision date.

Duplicate SDSs, in several cases, had managers at some Company Sites operating with SDSs older than those already held by colleagues at other Sites.

Report of duplicate SDSs

Duplicate SDSs of the same product

Duplicate SDSs at various production sites

Results of the demultiplexing process

The number of SDSs persisting downstream of duplicate elimination is 554 documents, a reduction of more than 22 percent.

Due to the elimination of older SDSs, in cases of duplicate SDSs, the age index is also improved from about 4.5 years to just over 3.5 years (Figure 9).

Against the elimination of duplicate SDSs, it is seen that only in the case of a single product are there 2 SDSs, and, as noted in the relevant detail, this is correct, as it is the same product (in the actual case it was a substance) from two different manufacturers.

The company is now in possession of "cleaned up" data to assess whether and how to proceed with an activity to update the portfolio of owned SDSs.

SDS-FullService for the management of Safety Data Sheets (SDS)

Indexing of SDSs

Automatic extraction and digitalization of information from Safety Data Sheets (SDS)

Centralized SDS collector and manager

Centralized and up-to-date binder of your Safety Data Sheets (SDS): the whole company can access and manage chemical data

Ongoing monitoring of MRSLs

Continuous monitoring of your hazardous substances with cross-checking against MRSLs of interest to you and automatic notifications of changes that have occurred

Access to SDSs for all users

Access to SDSs for all workers and authorized users

Automatic delivery of SDSs

Automatic and secure delivery of SDSs to customers and all product recipients, complies with REACH reg. and CEFIC, FECC and DUCC recommendations

Searching for and uploading SDSs

We retrieve missing SDSs or necessary updates by contacting the supplier

Start up services

we digitalize, we survey and catalog the SDSs present in the company, eliminating duplicates, unnecessary and obsolete ones, as well as searching for missing SDSs and new versions

Professional Services

The services of our Chemical Regulatory Partners: a team of REACH, CLP, environmental regulations, health and safety experts

Our team is here to help you manage SDSs and keep track of hazardous substances!

Benefits of SDS-FullService Cloud Solutions.

24/7 Availability

Available 24 hrs a day, 7 days a week. Access information when you need it, wherever you are.

A scalable and rapidly deployable solution

Available in different configurations suitable for all companies, including with SSO to automatically provide and revoke access to employees.

Ease of use

Use the service immediately, without training activities.

Rapid return on investment

Reduce time-consuming manual tasks and automate SDS management.

Tutorial & Interface

Multilingual interface, Tutorial with movies illustrating the operation of the service.

Low cost of ownership

With no software to install or maintain, with immediate access to new implementations and features.