Occupational safety and health

Management of a centralized digital repository of SDSs, updated and accessible to all staff

Holcim

Challenge

In the construction industry, the management of Safety Data Sheets (SDS) is a critical aspect that is critical to ensuring workplace safety and regulatory compliance. For Holcim, a global leader in the production of construction materials, maintaining an up-to-date and accessible SDS repository at each plant had become complex and time-consuming. The ideal solution had to be efficient and integrated, minimizing the impact on managers' daily operations.

Solution

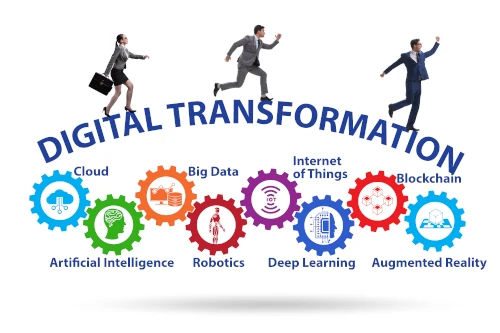

In partnership with Every SWS, Holcim implemented SDS-FullService, a scalable cloud-based system that enables centralized and up-to-date SDS management for all production sites. This advanced solution has transformed information storage into an agile and transparent process, helping to ensure secure and timely distribution of necessary data to all levels of the company.

"By partnering with Every SWS, SDS management has become simple, allowing us to streamline processes, free ourselves from repetitive tasks and protect ourselves from potential risks."

Riccardo Bianchi

Plant Manager and Employer

Holcim: innovation and sustainability in the construction industry

Holcim is a global leader in providing sustainable and innovative solutions for the construction industry. With the goal of building progress for people and the planet, its employees are on a mission to decarbonize the construction industry while improving people's living standards. The company enables its customers to build better while using less material thanks in part to its wide range of low-carbon solutions that apply circular economy principles such as ECOPact to ECOPlanet. With its innovative systems, Holcim makes buildings more sustainable by promoting energy efficiency and ecological adaptations. With sustainability at the heart of its strategy, the Holcim Group is achieving zero net emissions with targets validated by the Science Based Targets (SBTi) initiative.

The Italian subsidiary Holcim Italia SpA employs more than 300 people in two cement plants, a grinding center in Merone (CO) and a full-cycle production plant in Ternate (VA), as well as aggregate quarries, concrete plants and import terminals.

Requirement: integrate and simplify SDS management.

With more than 600 SDSs distributed across different production sites and under the supervision of various managers, Holcim needed a centralized and easily managed solution. The main objectives were:

Reorganize and update a single repository, ensuring controlled access to all SDSs

Avoid differences between versions of SDSs for the same product distributed in multiple establishments

Minimize the operational impact on the routines of plant managers

Why Holcim chose SDS-FullService: the benefits of an advanced solution

After careful evaluation of available solutions, Holcim chose SDS-FullService from Every Software Solutions to simplify and improve SDS management, streamlining the entire process of storing and distributing safety information.

At the heart of SDS-FullService is a cloud solution that provides scalability, security, and rapid deployment. The system offers a centralized collector that manages SDSs received from suppliers, automatically extracts and indexes key content, and builds a digital archive of substances and mixtures, facilitating access and search. In addition, the system includes configurable processes for managing the approval cycle.

One of the strengths of SDS-FullService is the range of ongoing services it offers, which include the constant search for updates from suppliers, the automatic insertion of new versions, and the archiving of obsolete SDS. This continuous approach allows Holcim to keep its SDS archive up-to-date without placing a strain on internal resources.

In addition, the SDS Viewer makes it easy to distribute SDSs to all workers with an intuitive interface and integration with corporate user authentication systems, allowing instant access.

These elements made SDS-FullService the ideal choice for Holcim, which can now manage SDS in an agile way, allowing managers to focus on more value-added strategic activities.

Results and benefits: an optimized process for every level of the company

By implementing SDS-FullService, Holcim has achieved a significant evolution in SDS management, streamlining processes at all levels of the company. The centralized solution has simplified access to essential product information, greatly reducing search and management time. Now, every SDS document is up-to-date, easily searchable and immediately available with a single click, eliminating duplication and outdated versions and ensuring that critical information can be accessed anywhere, by anyone authorized and at any time.

The adoption of an integrated approval workflow has brought greater transparency and control at every stage of the process. After new SDSs are received, the system runs an automated digitalization process that includes extraction and indexing of key data, making them immediately searchable and facilitating access to information. Each step of the workflow-from digitalization to final validation and approval-is supported by automatic notifications and real-time alerts. This system ensures that every HSE manager and H&S is always informed and can make quick and informed decisions, improving operational safety.

Among the main benefits gained, comparison of SDSs enables immediate and accurate verification of differences between versions, simplifying approval of new products and upgrades.

Finally, the SDS Viewer has speeded up the distribution of Safety Data Sheets, making it intuitive and accessible for all workers. Integrated with corporate user authentication systems (SSO), it allows employees to easily access SDSs, saving time and reducing the need for technical training. Immediate presentation of key content allows workers to quickly locate information of interest to them.

Overall, this centralized and structured management has not only reduced the operational burden associated with SDSs, but has also improved the company's safety and regulatory compliance, enabling Holcim to continue its mission of sustainable and safe growth.

Every success is continuous growth

The flexibility of SDS-FullService has enabled Holcim to quickly integrate new production sites, ensuring smooth and seamless operation, even during expansion phases.

In addition, over the years, Holcim has continued to update and improve its internal processes by progressively adopting the new features released by Every SWS. This approach has enabled constant improvement of approval and distribution processes, optimizing management effectiveness at all levels of the company.

Currently, Holcim's SDS repository includes about 1,000 SDSs, issued by about 200 manufacturers, and involves a dozen users with active roles in the approval cycle, in addition to making SDSs available to all staff.

"Every SWS stood out for its ability to listen, its willingness to dialogue with technical and non-technical figures, and the speed with which we were able to integrate the solution."

Marco Bestetti

Environmental Coordinator and H&S

Holcim continues to strengthen its commitment to safety and operational efficiency, having found in Every SWS a reliable and proactive partner capable of responding flexibly and quickly to the needs of a constantly evolving reality.